If there's a problem with the roof solar mounting system, is it easy to replace only the affected parts rather than having to dismantle the entire system?

If There’s a Problem with the Roof Solar Mounting System, Is It Easy to Replace Only the Affected Parts Rather Than Dismantling the Entire System?

Understanding the Structure of a Roof Solar Mounting System

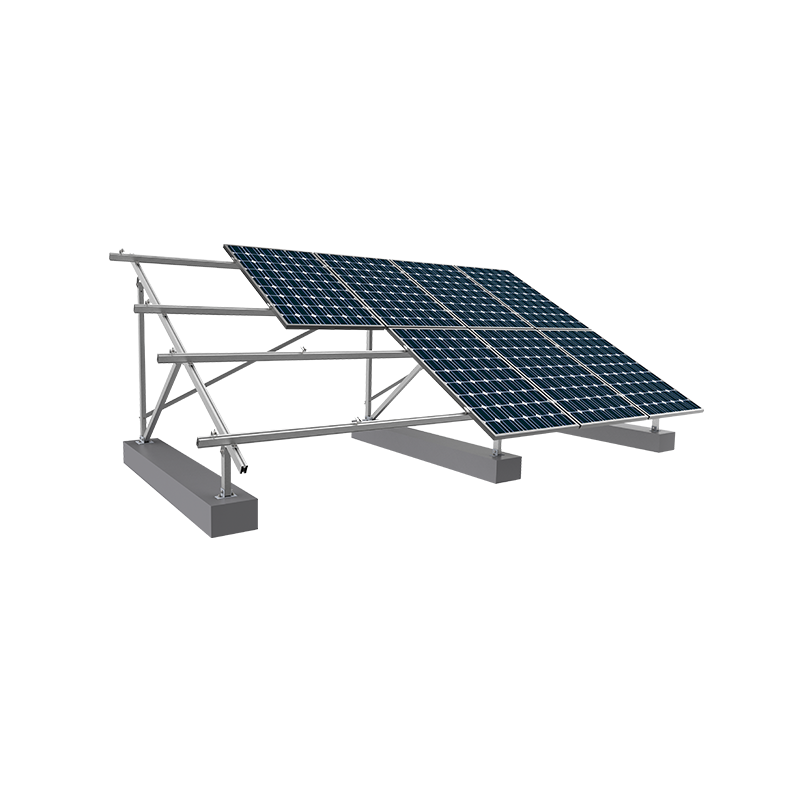

A roof solar mounting system is a structural framework designed to secure photovoltaic modules to a building roof while maintaining stability, alignment, and long-term reliability. It typically consists of rails, mounting brackets, clamps, fasteners, roof attachments, and sometimes adjustable connectors. These components work together to distribute loads, accommodate thermal expansion, and adapt to different roof types such as metal, concrete, or tiled roofs.

The modular nature of most modern roof solar mounting systems plays a key role in determining whether partial replacement is feasible. Systems designed with standardized interfaces and independent components are generally more suitable for localized repairs than those relying on continuous or integrated structures.

Common Types of Issues in Roof Solar Mounting Systems

Problems in roof solar mounting systems usually originate from mechanical stress, environmental exposure, installation errors, or material fatigue over time. Typical issues include corrosion of fasteners, loosening of clamps, deformation of rails, damage to roof attachments, or seal degradation at penetration points.

In many cases, these issues are localized rather than system-wide. For example, corrosion may occur in areas exposed to standing water, while loosening may result from vibration or thermal cycling at specific module positions. Understanding the scope of the issue is essential before deciding whether a partial replacement is possible.

Modular Design and Its Impact on Replaceability

Modern roof solar mounting systems are often designed with modularity in mind. Rails are segmented, clamps are independent, and roof attachments are installed at discrete points. This modular approach allows individual components to be removed and replaced without disturbing the entire structure.

When a mounting system uses standardized rail profiles and clamp designs, affected parts can usually be accessed by removing nearby modules only. This reduces labor time and minimizes the risk of introducing new alignment issues elsewhere in the system.

Role of Fasteners and Connection Methods

The ease of replacing affected parts is closely related to the type of fasteners and connection methods used. Bolted connections with accessible hardware are generally easier to service than riveted or welded joints. Stainless steel bolts, aluminum T-slots, and slide-in nuts are commonly used to facilitate adjustments and maintenance.

If fasteners are seized due to corrosion or overtightening, replacement may become more complex. In such cases, removing a single damaged fastener might require partial disassembly of adjacent components. Proper material selection and installation torque control significantly influence long-term serviceability.

Impact of Roof Type on Partial Replacement

The roof structure itself affects how easily mounting components can be replaced. On metal roofs with clamp-based attachments, individual clamps or rails can often be replaced without penetrating the roof or disturbing other mounting points.

On tiled or concrete roofs, roof hooks or anchors are usually installed beneath the roofing material. Replacing these components may require temporary removal of tiles or localized roof work. While this does not necessarily require dismantling the entire system, it does demand careful handling to avoid roof damage.

Accessibility of Affected Components

Accessibility is a practical factor that determines whether partial replacement is realistic. Components located at the edge of the array or near maintenance walkways are generally easier to access. Parts located in the center of large arrays may require removal of multiple modules to reach the damaged area.

Even in these cases, the mounting system itself often remains intact. The ability to temporarily remove modules without altering the mounting framework is a key advantage of systems designed for serviceability.

Compatibility and Availability of Replacement Parts

Partial replacement depends on the availability of compatible replacement parts. Systems based on proprietary components may pose challenges if the original manufacturer changes designs or discontinues products. Standardized mounting profiles and widely used clamp dimensions improve the likelihood of sourcing replacement parts years after installation.

When replacement parts are dimensionally compatible but differ slightly in surface finish or design, they can still function effectively, although visual consistency may be affected. From a structural perspective, compatibility in load capacity and material properties is more critical than appearance.

Structural Integrity After Partial Replacement

Replacing only affected parts raises questions about structural integrity. A well-designed roof solar mounting system allows components to function independently while maintaining overall load distribution. When a damaged rail segment or clamp is replaced, the surrounding structure continues to share loads as intended.

However, improper replacement practices, such as mismatched materials or incorrect torque application, can introduce stress concentrations. Following manufacturer guidelines and engineering specifications is essential to ensure that partial replacement does not compromise system performance.

Maintenance Planning and Documentation

Systems that include detailed installation documentation and as-built drawings are easier to maintain. These records help technicians identify component types, fastening methods, and load paths, making targeted repairs more efficient.

Without proper documentation, identifying the correct replacement method may require exploratory disassembly, increasing labor time and the risk of unintended damage. Maintenance-friendly systems prioritize clarity and traceability in their design.

Comparison Between Modular and Integrated Mounting Systems

| Design Aspect | Modular Mounting System | Integrated Mounting System |

| Component Independence | High, components can be replaced individually | Low, components are interdependent |

| Repair Scope | Localized to affected area | Often requires broader disassembly |

| Maintenance Flexibility | Adaptable to partial replacement | Limited flexibility |

| Long-Term Serviceability | Favorable with proper part availability | More restrictive over time |

Influence of Installation Quality on Future Repairs

The original installation quality has a direct impact on how easily parts can be replaced later. Correct alignment, appropriate fastener torque, and proper sealing all contribute to long-term stability. Systems installed with excessive force or misalignment may develop issues that complicate later repairs.

Installers who follow recommended spacing and leave adequate tolerances for thermal expansion help ensure that components can be removed and reinstalled without binding or deformation.

Safety Considerations During Partial Replacement

Replacing individual components on a roof-mounted solar system requires careful attention to safety. Temporary removal of modules must be done without stressing electrical connections. Mounting systems designed with clear separation between electrical and structural elements reduce the risk during maintenance.

Stable anchoring points and predictable load paths allow technicians to work on specific areas without compromising the overall stability of the array.

Cost and Time Implications of Partial Replacement

From a cost perspective, partial replacement is generally more efficient than dismantling an entire system. Labor time is reduced, fewer components are disturbed, and system downtime is minimized. These advantages are particularly important for commercial or industrial installations where operational continuity matters.

However, if a system lacks modularity or uses outdated components, the cost savings of partial replacement may be limited. In such cases, broader upgrades may be considered as part of a long-term maintenance strategy.

Long-Term Design Trends Supporting Replaceability

Design trends in roof solar mounting systems increasingly emphasize lifecycle considerations. Engineers and manufacturers recognize that systems must be maintained over decades. As a result, designs favor standardized components, accessible fasteners, and clear replacement paths.

This shift reflects the growing importance of sustainability not only in energy generation but also in system maintenance and resource efficiency.

Practical Evaluation Before Deciding on Replacement Scope

Before deciding whether to replace only affected parts or undertake broader disassembly, a thorough inspection is essential. Evaluating corrosion extent, structural deformation, and fastener condition helps determine whether issues are isolated or systemic.

In many cases, roof solar mounting systems are designed to support targeted repairs. When supported by compatible parts and proper procedures, replacing only the affected components is both feasible and practical, avoiding unnecessary disruption to the entire installation.

English

English 日本語

日本語 Deutsch

Deutsch عربى

عربى 中文

中文