How to install a mountain PV mounting system on a steep slope or complex terrain?

Understanding the Challenges of Mountain PV Mounting Systems

Installing a mountain photovoltaic (PV) mounting system on steep slopes or uneven terrain presents a unique set of engineering and logistical challenges. The variable soil composition, unpredictable weather conditions, and steep gradients require specific designs and installation techniques. Before beginning installation, it is important to evaluate the site’s slope stability, soil structure, and exposure to sunlight. These assessments help determine the most appropriate foundation type and racking configuration. Since mountain PV projects are often located in remote areas, accessibility and transportation of materials should also be considered during planning to ensure safe and efficient construction.

|

|

Site Survey and Terrain Assessment

The first critical step is conducting a detailed topographic survey. Surveyors use advanced mapping tools such as GPS and LiDAR to create accurate 3D terrain models. These models help identify slope variations, potential obstacles, and areas prone to erosion or landslides. The data collected enables engineers to customize the mounting system layout and foundation type. In steep terrains, identifying stable zones for foundation anchoring minimizes future structural stress. A thorough site survey also helps determine the optimal orientation and tilt angle for maximum solar exposure, ensuring long-term energy yield.

Design Adaptation to Complex Topography

Unlike flat-ground PV installations, mountain PV mounting systems must adapt to irregular landscapes. Adjustable racking structures are often used to accommodate varying elevations while maintaining a uniform panel angle. The support frames are designed to follow the contour of the land, reducing the need for extensive grading. Engineers can use flexible row spacing to manage shadowing between arrays. This type of adaptive design enhances both the stability and efficiency of the installation. In some cases, segmented arrays are installed at different elevations to align with natural slopes, minimizing disruption to the environment.

Choosing the Right Foundation System

The foundation of a mountain PV mounting system depends heavily on soil type, slope angle, and geological conditions. For rocky or firm ground, anchor bolts or rock drills may be used to secure the frames. In softer soils, ground screws or reinforced concrete footings offer better load distribution. The key is to select a foundation that provides adequate holding capacity without causing excessive disturbance to the terrain. Engineers also consider water drainage and erosion control during foundation design. The table below compares common foundation types used in steep-slope PV projects.

| Foundation Type | Suitable Terrain | Main Features | Installation Method |

|---|---|---|---|

| Ground Screws | Soft or mixed soil | Easy to install and remove | Drilled and screwed into the ground |

| Rock Anchors | Hard or rocky terrain | High load capacity | Drilled directly into rock layers |

| Concrete Footings | Steep slopes with loose soil | Strong structural support | Cast-in-place concrete with rebar |

| Steel Piles | Moderate slope with compacted soil | Durable and corrosion-resistant | Driven or drilled depending on soil |

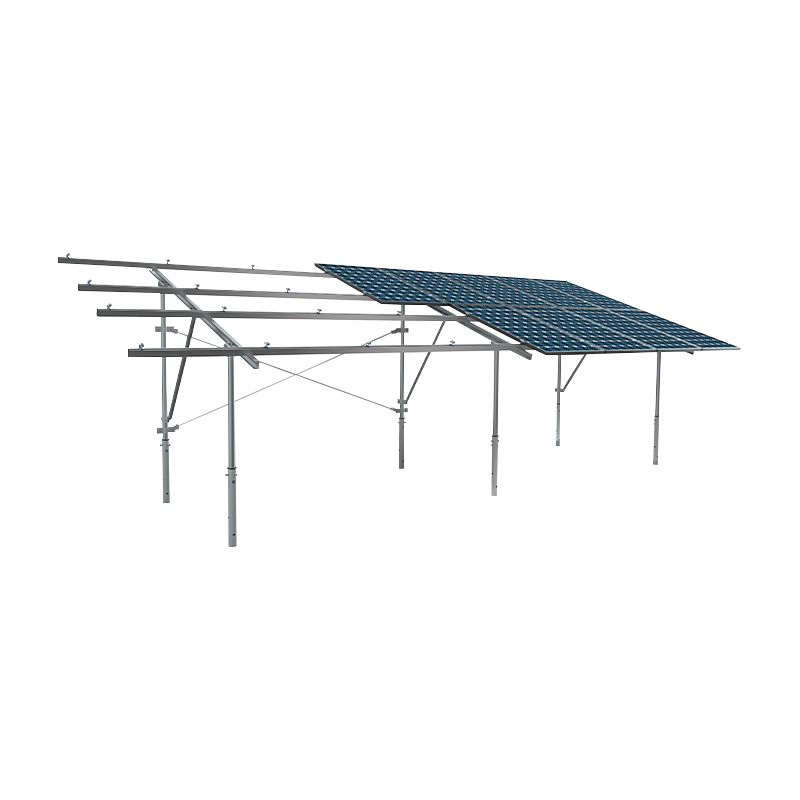

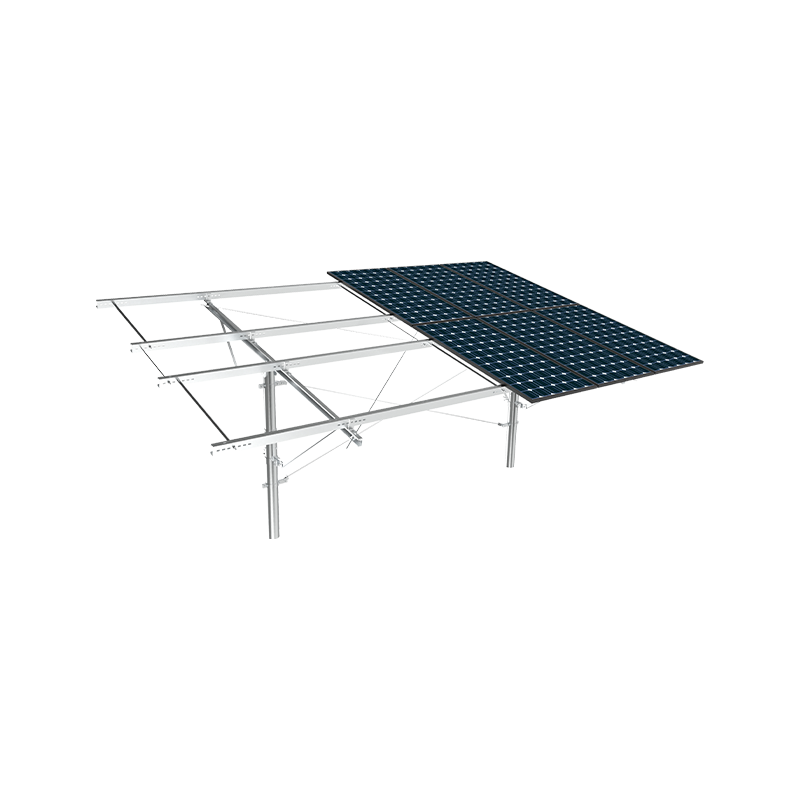

Racking System Installation

After the foundation is in place, the racking system is assembled to support the PV modules. The installation must ensure structural integrity despite uneven ground. Mounting rails are aligned and adjusted individually to maintain consistent panel tilt and orientation. In some designs, telescopic legs or adjustable joints are used to compensate for differences in height between foundations. Fastening systems are checked for proper torque to prevent loosening due to vibration or wind loads. Proper grounding of the racking structure is also essential for safety and compliance with electrical standards.

Optimizing Panel Layout for Slope Conditions

Optimizing the panel layout helps balance energy production with mechanical stability. In steep terrain, the array spacing must be carefully calculated to prevent shading from upper rows. The tilt angle can be adjusted according to the slope direction to ensure optimal sun exposure. For south-facing slopes, a slightly reduced tilt may help maintain uniform energy collection. For north-facing slopes, higher tilt angles may be required to capture more sunlight. Proper spacing and alignment not only improve efficiency but also reduce wind resistance and mechanical stress on the system.

Managing Water Drainage and Soil Erosion

Effective water management is crucial in mountain PV installations. Poor drainage can lead to erosion around the foundation and compromise structural stability. Installing drainage ditches, retaining walls, or vegetation barriers can help control runoff. Engineers often design the mounting layout to follow the natural water flow of the slope, avoiding water accumulation beneath the structures. In addition, protective mats or geotextiles may be applied around the foundations to prevent soil displacement. Maintaining proper drainage reduces long-term maintenance needs and extends system lifespan.

Electrical System Considerations

The electrical design of a mountain PV system must account for elevation changes and longer cable runs. Flexible conduit and weather-resistant cabling are used to handle variations in terrain and prevent moisture ingress. Junction boxes are positioned in accessible areas for easier inspection and maintenance. Grounding and bonding must comply with electrical safety standards to prevent potential faults. The use of microinverters or string optimizers can help maintain stable performance even if some panels are partially shaded by terrain or vegetation.

Installation Safety and Equipment Handling

Working on steep or uneven terrain increases the risk of slips and falls. Safety measures include using harnesses, ropes, and secure anchors for workers. Heavy equipment such as cranes and excavators should be carefully positioned to avoid soil collapse or overloading the slope. Lightweight materials and modular designs are often preferred for ease of transport and assembly. Training personnel in slope safety and emergency procedures ensures that installation proceeds efficiently without compromising worker well-being.

Quality Control and Inspection

Once installation is complete, a thorough inspection ensures that all structural and electrical components meet design requirements. Each foundation and frame connection is checked for stability and alignment. Electrical circuits are tested for continuity and insulation resistance. Monitoring systems may be installed to track real-time performance and detect potential faults. In mountain environments, regular inspections help identify issues such as soil movement, corrosion, or vegetation growth that may affect performance over time.

Maintenance and Long-Term Performance

Mountain PV systems require ongoing maintenance to preserve their efficiency and safety. Periodic cleaning of panels helps maintain energy output, especially in areas prone to dust or snowfall. Inspecting foundations and support structures for signs of wear or shifting ensures long-term reliability. Drainage systems should be kept clear to prevent erosion. The use of remote monitoring tools allows operators to detect and address performance deviations quickly. With proper care, a mountain PV mounting system can operate effectively for decades.

Environmental Considerations and Sustainable Design

Installing PV systems on mountains requires careful consideration of environmental impact. Minimizing soil disturbance, preserving vegetation, and using recyclable materials contribute to sustainable project development. In some projects, low-impact installation techniques are employed to avoid heavy grading or deforestation. Proper site restoration after installation helps maintain ecological balance. By integrating energy generation with environmental preservation, mountain PV systems can provide renewable energy while protecting natural landscapes.

| Key Installation Step | Main Objective | Critical Factor |

|---|---|---|

| Site Survey | Accurate terrain mapping | Topographic precision |

| Foundation Installation | Stable structural support | Soil and slope compatibility |

| Racking Assembly | Uniform tilt and orientation | Height adjustment precision |

| Panel Layout | Maximized sunlight exposure | Shadow management |

| Drainage Management | Prevent erosion and flooding | Water flow control |

Integrating System Monitoring and Automation

Modern mountain PV installations often include monitoring and automation systems to enhance performance management. Sensors track environmental conditions such as temperature, sunlight, and wind speed. Automated systems can adjust operational parameters or alert maintenance teams when irregularities occur. Using real-time data enables operators to optimize energy production and detect mechanical or electrical issues early. This integration helps maintain efficiency even under challenging mountain conditions.

English

English 日本語

日本語 Deutsch

Deutsch عربى

عربى 中文

中文