Ground PV Mounting System Suppliers

-

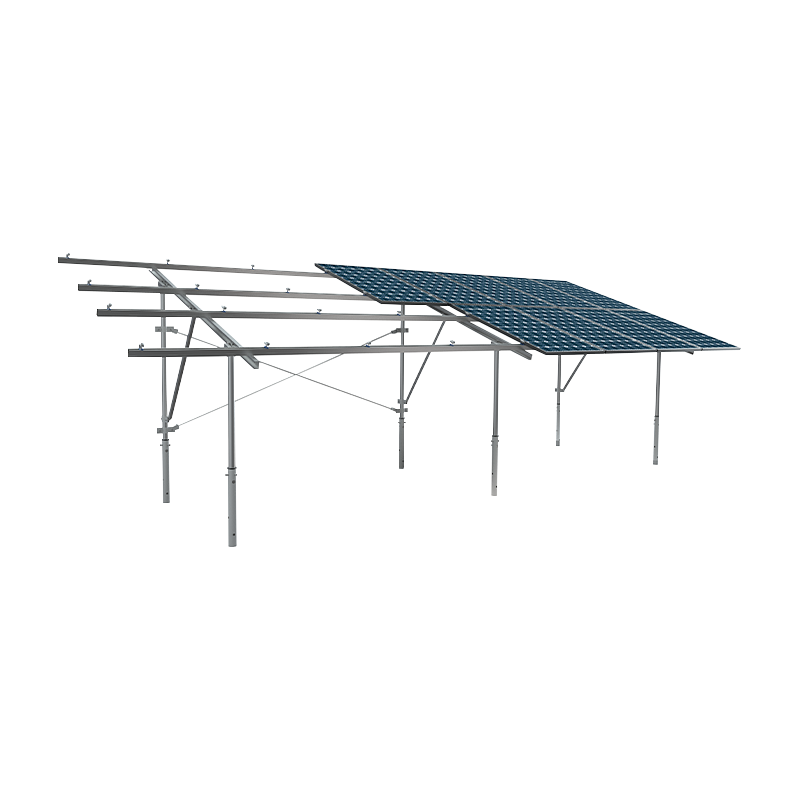

Product Highly resistant to wind and sand fixed PV MountingThe Highly resistant to wind and sand fixed PV Mounting is designed for extreme environments such as deserts and Gobi. It is made of thickened hot-dip galvanized steel or aluminum-magnesium-zinc material to resist strong wind and sand erosion and ultraviolet aging. It is suitable for soft sandy foun...View More

-

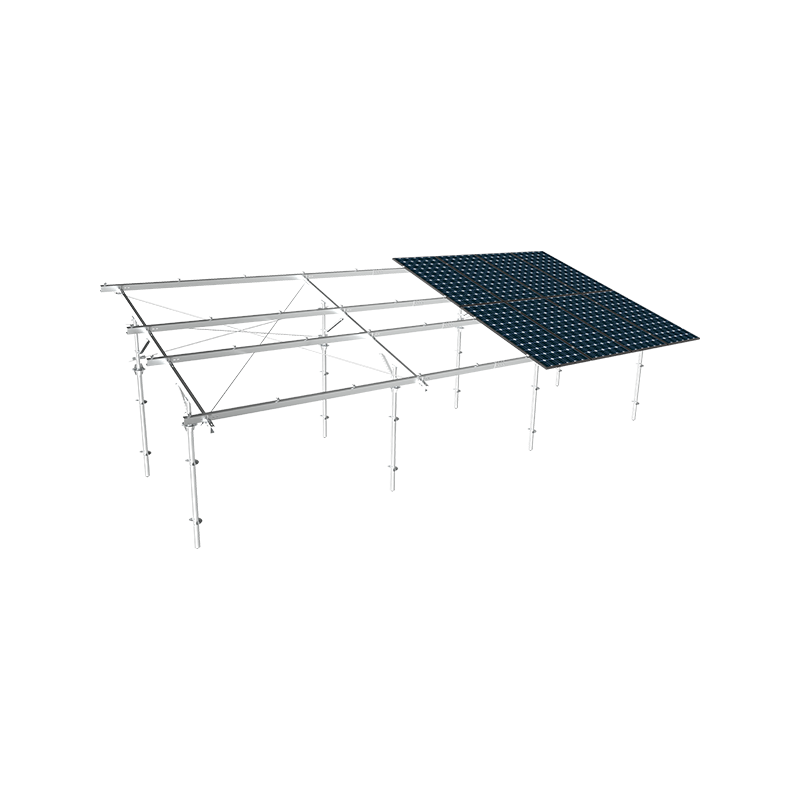

Product Double Column PV MountingDouble Column PV Mounting adopts a symmetrical double column structure, and the overall rigidity is enhanced by transverse connectors. The load-bearing and wind-resistant performance is significantly better than that of a single column. The main body is galvanized steel or aluminum alloy, which is s...View More

-

Product Fishery-solar Hybrid PV MountingFishery-solar Hybrid PV Mounting system is an integrated solution designed for the scenario of "water power generation and underwater aquaculture". It adopts a high bracket structure to support photovoltaic modules to be erected above fish ponds, lakes and other waters. The main body of the bracket ...View More

-

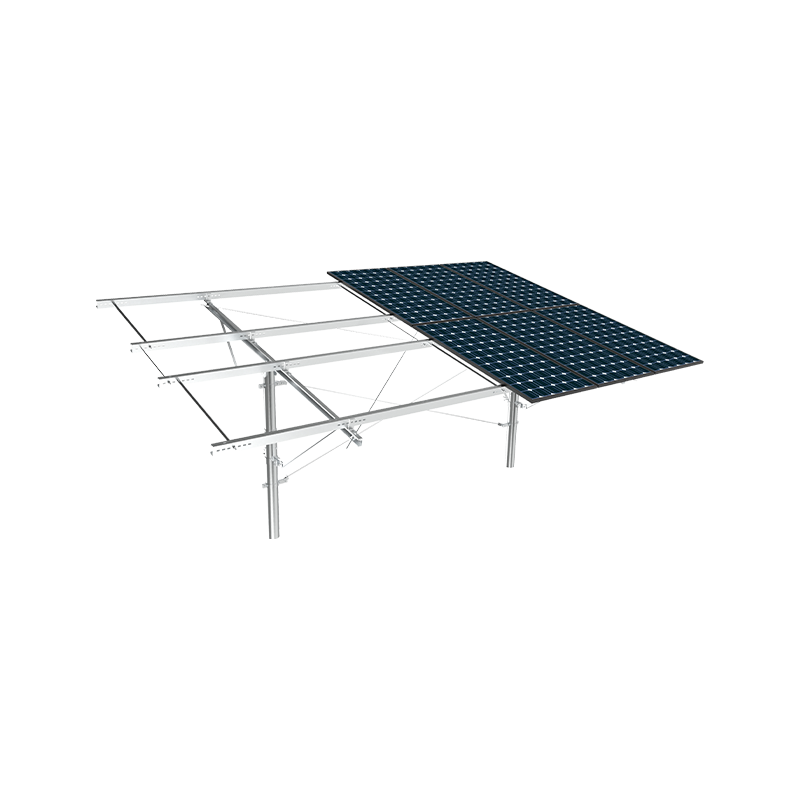

Product Agricultural-solar Hybrid PV MountingAgricultural-solar Hybrid PV Mounting is a support system designed for the collaborative scenario of "photovoltaic power generation + agricultural planting". It adopts a high-ground structure (usually 2.5-4 meters) to ensure that the crops below are well-lit and that agricultural machinery can pass ...View More

-

Product Single Column SleeveSingle Column PV Mounting uses independent columns as the core support, with a simple structure and economical materials, suitable for low slopes or flat terrain. with strong corrosion resistance, and the diagonal brace reinforcement improves the ability to resist side winds. It is suitable for smal...View More

As China Ground PV Mounting System Suppliers and Ground Mounted Factory, Founded in 2009, Dongsheng New Energy is a high-tech enterprise specializing in the design, research and development, manufacturing and integrated installation of distributed photovoltaic power generation system. It is determined to provide suitable and reliable support solutions and high-standard photovoltaic support products for solar photovoltaic power stations.The company has an outstanding design team, products through ISO quality system certification, and has a number of patented technologies, widely used in roof photovoltaic system, ground photovoltaic system, carport photovoltaic system, fishing and light complementary photovoltaic system. The company is based on providing customers with integrated introduction of advanced management mode, can provide customers with integrated photovoltaic support system services from early monitoring, design, procurement, installation guidance to later maintenance, since its establishment, for thousands of domestic and foreign photovoltaic power station system data supply reliable products and solutions.

-

Is a roof PV mounting system suitable for coastal environments with high salt spray?Environmental Characteristics of Coastal Areas with High Salt Spray Coastal environments present specific challenges for construction materials and structural s...

-

Does the ground PV mounting system support large-span structural designs?Understanding Large-Span Structural Design in Ground PV Mounting Systems The question of whether a ground PV mounting system can support large-span structural d...

-

How does the corrosion protection treatment of carport PV mounting systems perform in long-term outdoor environments?Overview of Corrosion Challenges in Carport PV Mounting Systems Carport photovoltaic mounting systems are installed in open or semi-open environments where they...

-

How can the risk of structural loosening be controlled in ground-mounted PV mounting systems during long-term outdoor use?Understanding Structural Loosening in Ground-Mounted PV Systems Ground-mounted photovoltaic mounting systems are designed to support solar panels over long peri...

A complete explanation of the construction logic and installation method of the ground PV mounting system

Basic definition and application scope of ground pv mounting system

Ground pv mounting system refers to the load-bearing structure system used to build photovoltaic power stations in the surface environment, which is used to support solar panels and fix them at a predetermined angle and position to achieve stable and efficient photovoltaic power generation operation. Its application scope covers a variety of scenarios such as large centralized power stations, ground distributed projects, barren hills and wastelands development, agricultural composite photovoltaics, slope management power stations, and industrial park vacant land utilization.

Ground photovoltaic supports have become the main installation method for large photovoltaic power stations due to their flexible layout, large system capacity, and easy maintenance. Compared with small systems such as roofs and balconies, ground supports have higher technical requirements in structural design, safety control, and material selection.

Technical foundation and engineering capabilities of Taizhou Dongsheng New Energy

Taizhou Dongsheng New Energy has long been committed to the research and development, manufacturing and installation services of distributed photovoltaic power station support systems. The company has a research and development team with engineering background and structural design capabilities. The product system has passed ISO quality management system certification and has a number of photovoltaic support-related structure and connector patents.

In terms of ground pv mounting systems, Dongsheng New Energy has accumulated rich experience in project design and installation. It can provide customers with customized, modular and highly adaptable solutions according to different terrain, geological conditions and climate environments, covering the whole process of survey, design, manufacturing, transportation, installation and post-maintenance services.

Structural types of ground pv mountings

1. Fixed mounting system

Fixed type is the most widely used structural type at present. The mounting inclination angle is fixed and unchanged, which is suitable for areas with open land and relatively stable light resources. The advantages are stable structure, controllable cost and simple maintenance. According to different terrain conditions, it can be divided into south-facing arrangement, east-west arrangement or double-row design.

2. Adjustable angle mounting system

This type of mounting supports seasonal adjustment of the component inclination angle by manual or mechanical means, so as to adapt to the changes in the solar altitude angle and improve the power generation efficiency throughout the year. It is suitable for construction in mid- and high-latitude areas, especially in areas with large differences between winter and summer, and has high application value.

3. Tracking mounting system (single-axis/dual-axis)

The tracking mounting system drives the photovoltaic components to rotate with the sun's trajectory through an electric mechanism to maximize the efficiency of light capture. Although the initial investment of the system is high, the power generation efficiency can be increased by more than 15%. This system is more suitable for large centralized power stations and needs to be considered in combination with terrain wind speed and grid access conditions.

Material composition and performance requirements

Dongsheng New Energy mainly uses the following material configurations in the ground support system:

*Hot-dip galvanized carbon steel profiles: It has the characteristics of high strength, corrosion resistance, and strong construction stability, and is suitable for various complex geological and climatic environments.

*Aluminum alloy profiles (part of the project): It is used in areas with stable geology and high weight requirements, which is convenient for transportation and assembly.

*Stainless steel fasteners and connectors: Ensure the corrosion resistance and structural strength of the connection parts during the long-term operation of the system.

*Buried foundation or screw pile foundation: Select the foundation form according to the soil structure and load requirements. The former has good stability and the latter has high construction efficiency.

The design of the support system must strictly check the load according to local environmental parameters such as wind pressure, snow pressure, and earthquake intensity to meet the safety, durability and structural stability requirements of long-term operation.

Foundation type and adaptable environment

Different ground support systems require different foundation forms to ensure the stability of the overall structure:

1. Concrete foundation

Applicable to project areas with solid foundations and long-term land resources. The construction period is long, but the structure is stable and has good weather resistance.

2. Screw pile foundation

It is driven into the ground by mechanical screws, with a short construction period. It is suitable for projects with soft geology or low ground disturbance requirements. It is easy to dismantle or adjust later.

3. Anchor or column foundation

It is widely used in slopes, mountains or temporary projects. It can be flexibly arranged according to the terrain height difference to reduce the cost of land leveling.

Dongsheng New Energy can customize the foundation type according to the nature of the customer's land use and investment cycle, taking into account the convenience of construction and system reliability.

System installation process and construction control

1. Site survey and terrain analysis

Before construction, detailed measurement and geological evaluation of the project site are required to collect information such as terrain height difference, soil type, and hydrological data.

2. Structural design and layout optimization

According to the design principles such as component size, cable wiring, inverter layout, etc., layout drawings and foundation positioning coordinates are formulated to optimize component orientation and spacing.

3. Component installation and structural connection

After the mounting materials arrive at the site, foundation construction and structural assembly are carried out. Dongsheng New Energy adopts modular structural design, which can greatly improve the efficiency of on-site assembly.

4. Quality inspection and mechanical verification

During the construction process, node strength detection, verticality inspection, anti-corrosion treatment confirmation and other links are carried out to ensure that the overall structural accuracy and mechanical properties meet the design requirements.

Key points for post-maintenance and operation of ground pv mounting system

Although the structure of the ground mounting system is stable, in order to ensure the long-term safe operation of the photovoltaic system, the following maintenance work still needs to be carried out regularly:

*Regularly check whether the connectors are loose or corroded;

*Clean up debris on the surface of the component to prevent obstruction;

*Check whether the overall horizontal and vertical state of the mounting has changed;

*Monitor and handle abnormal conditions such as water accumulation and settlement in the foundation;

*Carry out special inspections after storms, ice and snow to prevent structural displacement or local damage.

After the project is delivered, Dongsheng New Energy can provide optional maintenance service packages to assist customers in establishing a complete operation and maintenance system.

Application cases and field effect feedback

Dongsheng New Energy has built multiple ground photovoltaic support projects in Jiangsu, Anhui, Hebei, Shandong, Yunnan, Southeast Asia and other regions, covering:

* Industrial and commercial park vacant land utilization power stations;

* Agricultural photovoltaic complementary greenhouse support systems;

* Corrosion-resistant support structures in special environments such as deserts and tidal flats;

Flexible support platforms supporting distributed energy storage systems. User feedback shows that this type of system has stable operation, durable structure, adaptability to various climatic conditions, and strong investment controllability and power income guarantee capabilities.

Future development direction and technology trends

The development direction of ground pv mounting systems is becoming increasingly diversified, and the following technical paths will be focused on in the future:

* Lightweight structure optimization design: reduce material costs and transportation costs while ensuring load-bearing safety;

* Intelligent tracking system combination: integrate AI algorithms and environmental sensors to achieve automatic light tracking at the angle of components;

* Integration of structure and agriculture: promote multifunctional mounting design that combines agriculture with power generation;

* Use of recyclable materials: use recyclable aluminum or recycled steel to reduce carbon emissions;

* Integrated integration solution: mounting system and components, energy storage, inverter, cable system are designed and delivered in a unified manner.

Construction and optimization path of ground PV mounting system adapting to multiple terrains

Basic functions and composition of ground pv mounting system

The ground pv mounting system undertakes the important tasks of fixing photovoltaic modules, bearing wind load, snow load and self-weight. It is mainly composed of foundation structure, columns, beams, connectors and mounting rails. Its design must not only meet the requirements of structural strength and stability, but also consider construction efficiency, material cost, transportation method and convenience of later maintenance. Common types of supports include fixed tilt supports, adjustable supports and tracking supports. The specific selection needs to be comprehensively evaluated based on geographical location, climatic conditions, project capacity and land use form.

The impact of different terrains on the construction of photovoltaic support systems

The construction requirements of ground photovoltaic power stations in different terrains are different, and differentiated technical requirements are put forward for the support system:

1. Flat terrain

Suitable for conventional pile foundations and large-scale mechanized construction. The structure is relatively standardized, and aluminum alloy or hot-dip galvanized steel structure can be used. Cost control is relatively easy and installation efficiency is high.

2. Hilly and sloping terrain

The terrain is undulating, which puts higher requirements on the adjustment ability and modular combination of the support system. Usually, adjustable columns, beams of different heights and separate foundation units are used. The height of the bracket needs to be adjusted according to the terrain to avoid obstruction and shadow effects.

3. Desert and Gobi

The wind and sand are strong, and the bracket needs to have strong wind resistance. The foundation often adopts cast-in-place piles, anchor foundations and other forms. The structure needs to be simple and solid to reduce wind resistance and dust accumulation.

4. Saline and humid areas

Highly anti-corrosion materials such as hot-dip galvanized steel or stainless steel components need to be selected. The structural design needs to consider moisture resistance, drainage and ground corrosion to extend the service life of the system.

Key points of terrain-adaptive structural design

1. Foundation design matching

In different terrains, the reasonable selection of foundation treatment and foundation form is the key to ensure the stability of the bracket system. Taizhou Dongsheng New Energy Technology Co., Ltd. combines the geological survey data of the project site to provide customers with a variety of foundation forms such as spiral piles, concrete piles, hammer piles or rock pre-buried anchor bolts to adapt to differences in rock thickness, groundwater level and bearing capacity.

2. Modular combination and adjustment mechanism

In order to achieve rapid installation and structural adaptation, multi-terrain brackets often adopt modular combination structures. Components of different sizes and angles can be assembled flexibly on site to ensure that the brackets are stably arranged on terrain with varying slopes and uneven terrain. The use of adjustment mechanisms such as retractable columns and porous angle steel connectors helps to achieve horizontal uniformity of the component array.

3. Inclination and orientation optimization

Under terrain restrictions, the inclination and orientation of fixed brackets may not be set uniformly. Through on-site layout software simulation and component layout optimization, shading can be effectively reduced and the overall system efficiency can be improved. Dongsheng usually uses BIM modeling and PV system design software to preview the bracket layout plan to improve the system output capacity.

Material selection and surface treatment technology

In multi-terrain application scenarios, the mechanical properties, corrosion resistance and service life of the bracket material are closely related. Hot-dip galvanized steel is still the mainstream material due to its economy and durability. For high-salt and high-humidity environments, higher zinc layer thickness or stainless steel can be selected, and surface passivation treatment can be performed.

Dongsheng uses self-designed hot-dip galvanized steel support systems in a large number of projects. The thickness of the zinc layer on the surface is not less than 80μm, and combined with fastener coating technology, the overall corrosion resistance is improved.

Construction process and efficiency control

Complex terrain is often accompanied by increased construction difficulty. In order to reduce the construction period and cost, the support system must have the characteristics of high pre-assembly rate, convenient on-site adjustment, and standardized installation tools. Pre-assembled parts can be assembled in the factory, and only splicing and leveling are required on site, which improves efficiency and reduces on-site errors.

Taizhou Dongsheng New Energy Technology Co., Ltd. has implemented the "module pre-assembly + fast placement" construction strategy in many mountain photovoltaic projects, effectively shortening the construction period and improving installation accuracy.

Structural durability considerations in system operation and maintenance

In the later operation and maintenance stage of the project, the stability of the support system structure, the looseness of the connectors and the anti-corrosion status have a great impact on the overall efficiency of the system. In order to reduce the maintenance frequency and operation and maintenance costs, inspection channels should be reserved in the design stage, easily replaceable connectors should be used, and lightning protection and grounding devices should be set up. Structural durability is not only related to the life of the bracket itself, but also affects the stability of the components and the safety of the system. Especially in areas with frequent strong winds and heavy rains, regular structural inspections and foundation reinforcement should be carried out.

Future development direction and intelligent integration

In the future, ground pv mounting systems will develop in the direction of lightweight, intelligent and standardized. The application of new materials such as high-strength aluminum alloys and composite materials will further improve structural efficiency. At the same time, the integration of intelligent equipment such as photovoltaic tracking systems and component cleaning systems will help improve power generation efficiency and operation and maintenance efficiency. Dongsheng is trying to introduce AI illumination modeling and terrain information system (GIS) analysis technology into the preliminary design of bracket layout to achieve a more scientific layout and improve energy utilization.

From structural adaptation to system optimization

The design of pv mounting systems that adapt to multiple terrains is not only a structural engineering challenge, but also a key link in improving system power generation efficiency and project feasibility. Through the system optimization of material selection, structural combination, installation technology and intelligent operation and maintenance, ground photovoltaic power stations can achieve a wider range of landing applications in different geographical environments.

As a participant in the field of distributed photovoltaic brackets, Taizhou Dongsheng New Energy Technology Co., Ltd. will continue to deepen its exploration in product standardization, customization capabilities and integrated services to provide sustainable bracket solutions for diverse terrains.

English

English 日本語

日本語 Deutsch

Deutsch عربى

عربى 中文

中文